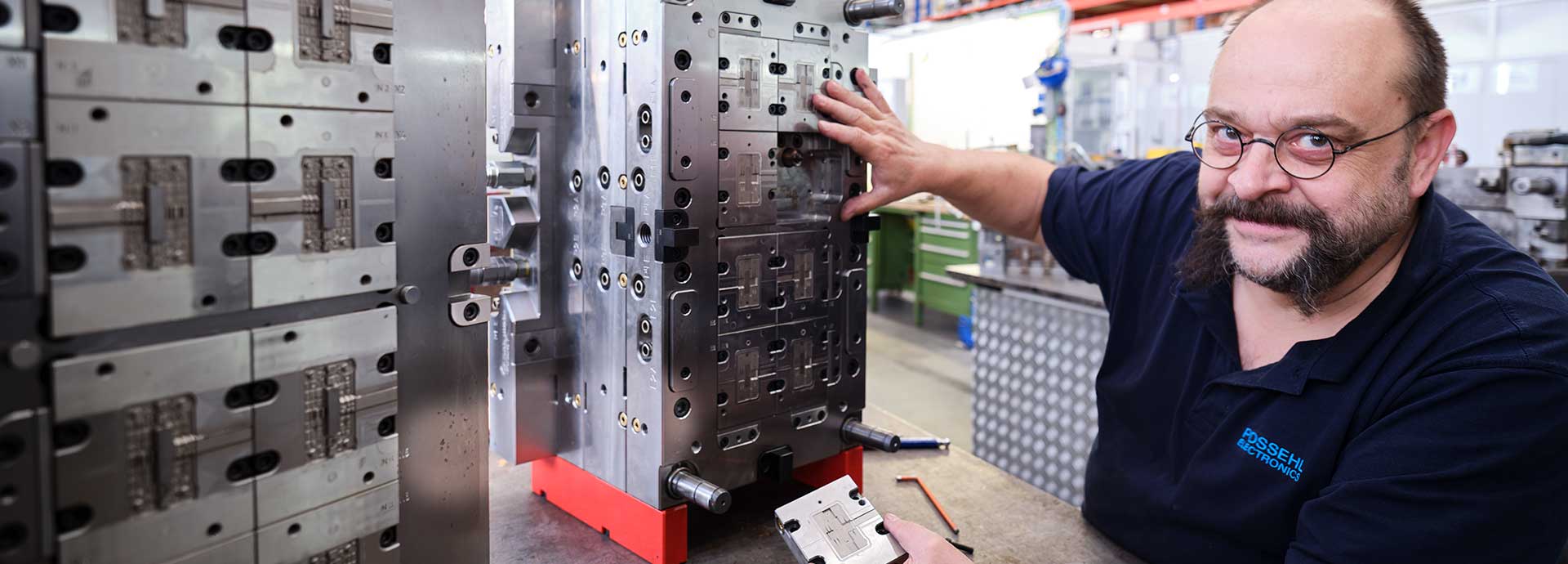

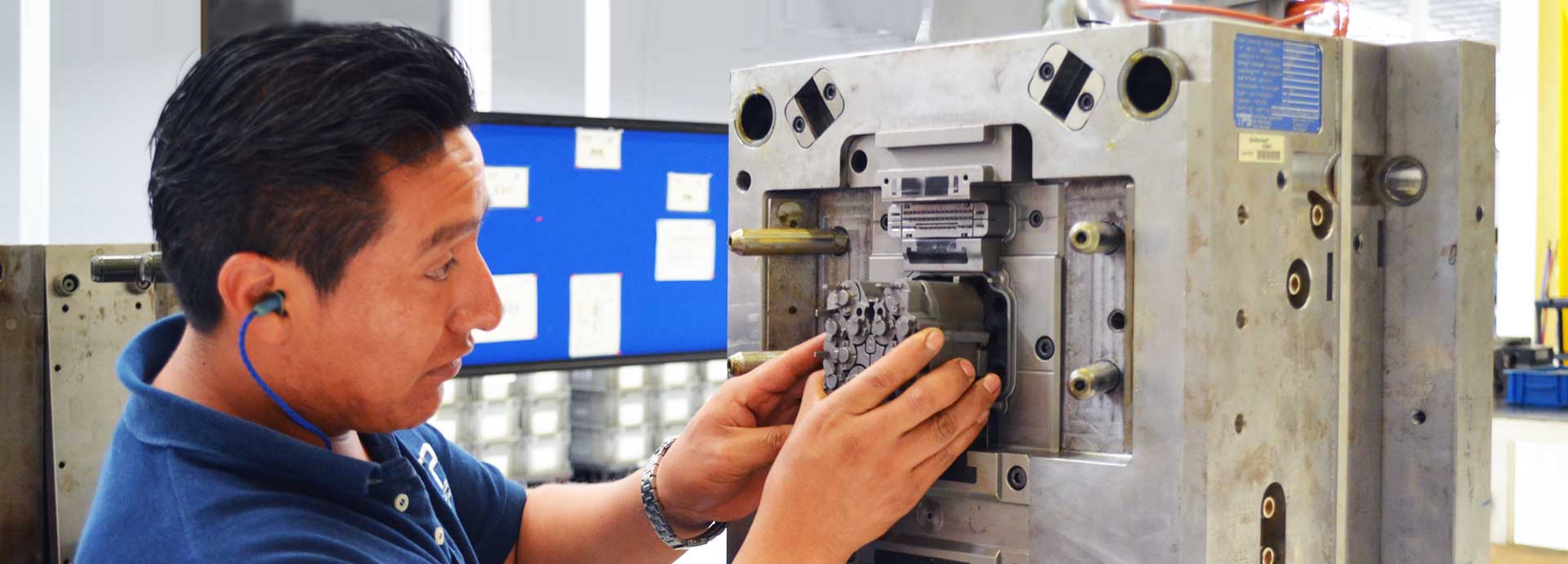

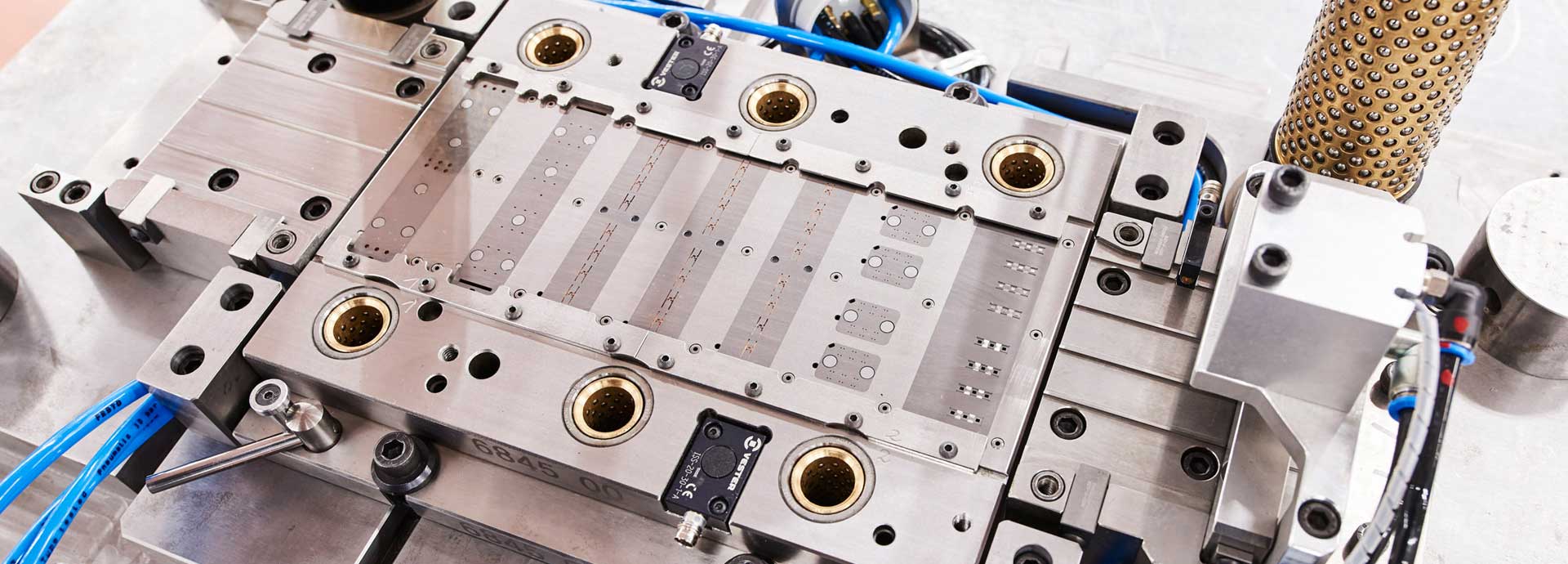

A core competence of Possehl Electronics is the manufacture of tools for all tool types

The manufacture of new tools and the internal maintenance of molding and stamping tools, mechatronic dpt, ensures independent maintenance and repair of our automation lines.

Materials

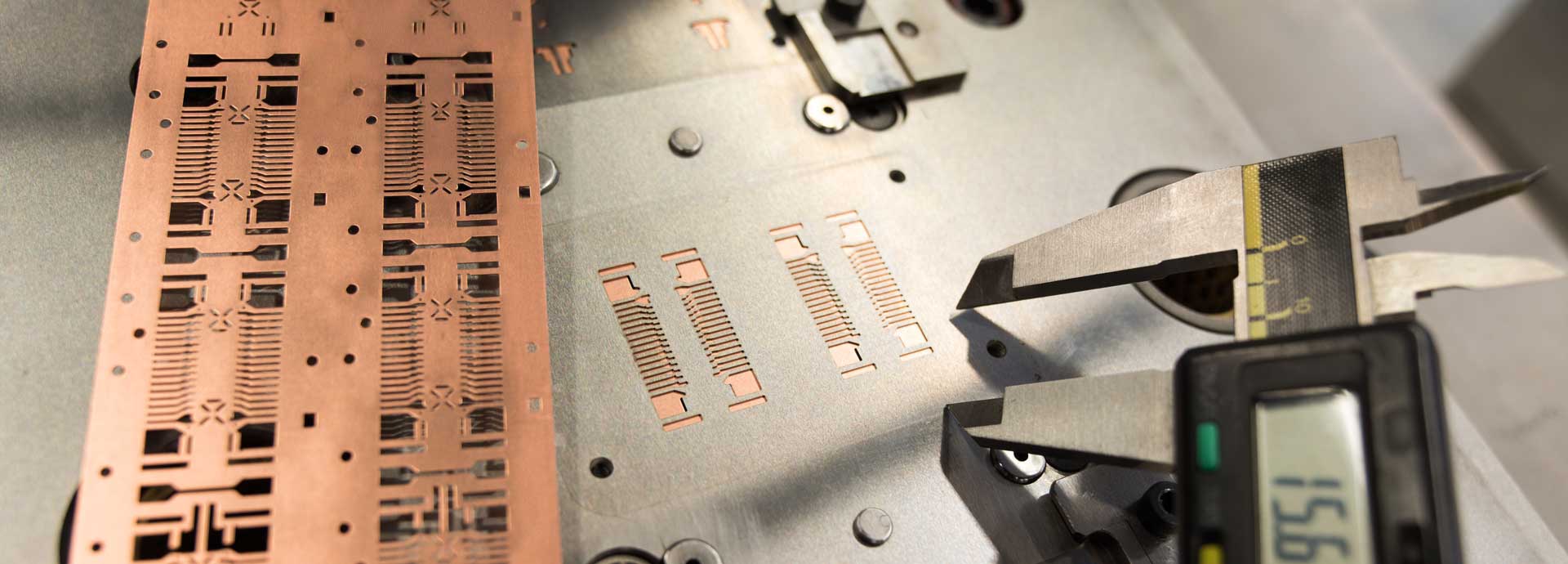

- Steel 1.2083, 1.2379, PM steel, carbide, special steels

- EDM wire from 0.03 mm

- Copper (tungsten and E-CU) and graphite electrodes

Tools

- Progressive stamping tools for a material thickness of 0.05 mm to 3.0 mm and a material width up to 160 mm

- Bending, assembly and cutting tools

- 2 and 3-component injection-molding tools

- Tools for duroplast and silicone products

- Reel-to-reel injection molds up to 128 cavities

- Hybrid injection molding parts with one upper part and up to three lower parts

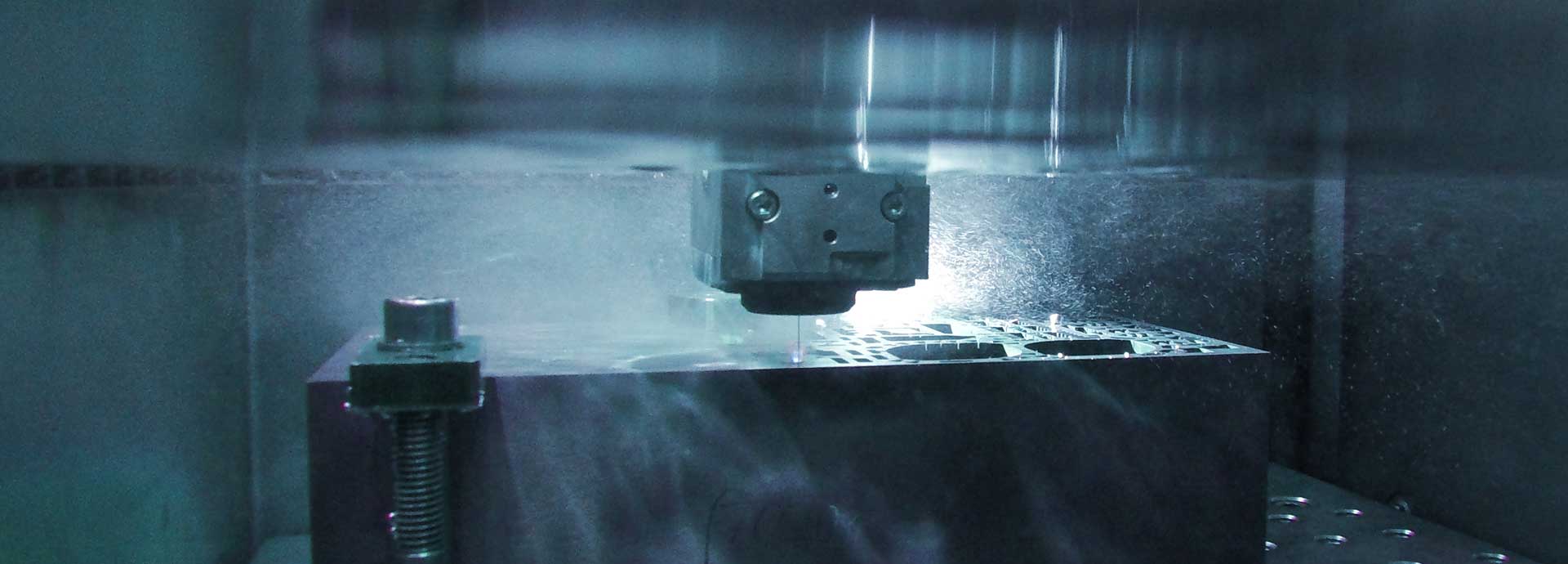

Machinery/Equipment

- Ultra-modern wire eroding machines

- Vertical eroding machines

- HSC milling machines

- Fully automatic cutting – eroding – measuring 24/7

- Surface grinders

- Profile grinding machines

Technology highlights

- 3D design with fully integrated CAD/CAM system

- Prototyping

- Modular PM tools with up to 700 individual fins

- Ratio of groove and fin width to material thickness of min. 0.8

- Continuous CAD/CAM environment in all process steps

- Close-to-production prototyping concepts including press-in zones

- Short FOT-to-PPAP throughput time due to 24/7 in-house production

- Reverse engineering by means of software, 3D and CT-Scan

- Use of ultra-modern electroplating technologies