In-house testing laboratories at Possehl Electronics ensure efficient development and continuous production monitoring

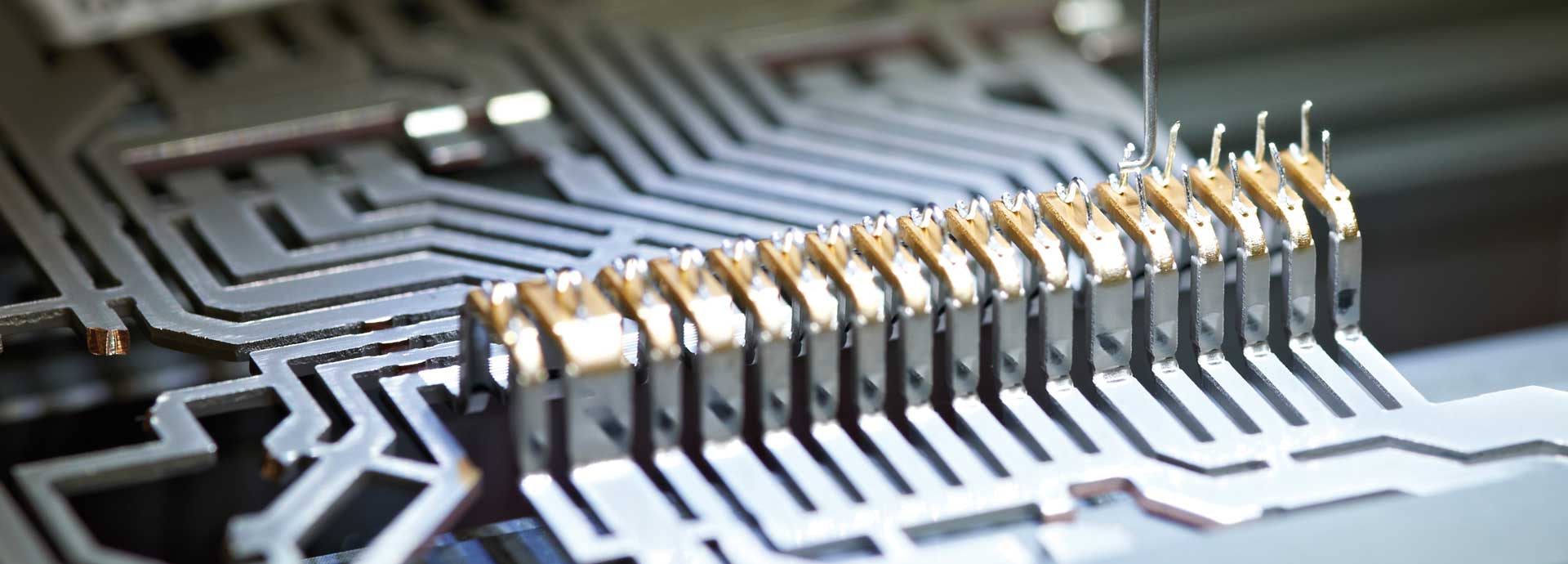

Testing technology

With our testing laboratories, Possehl Electronics has created the opportunity to qualify as an efficient development partner for new products and processes in-houseie and to systematically monitor processes from the prototype phase through to series production.

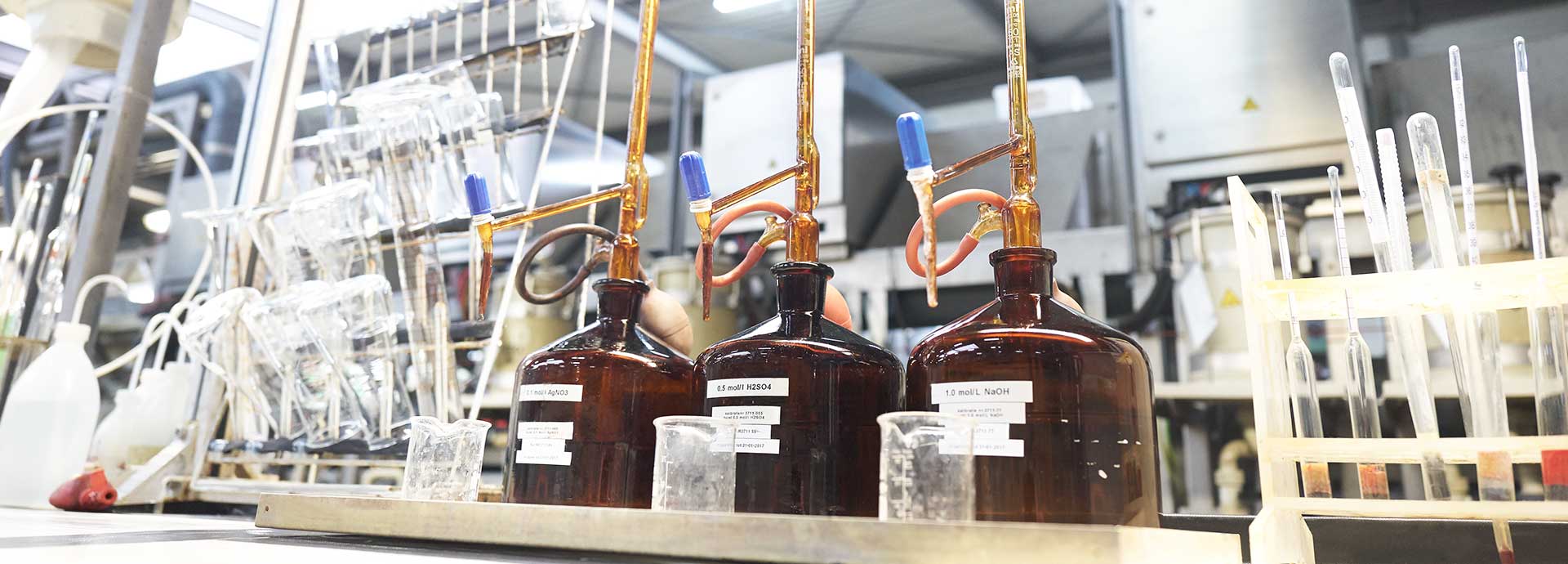

Testing laboratory for

- Technical cleanliness (particle testing according to VDA – Volume 19)

- Environmental Simulation – Development Laboratory (life endurance tests such as temperature, humidity, salt spray and tightness, metallography and electrical functional tetsts for custom applications)

- Testing technology (leak testing, electrical testing, metallography, microscopy and destructive tension and pressure testing among others)

- Climate chamber

- CT Computed Tomography

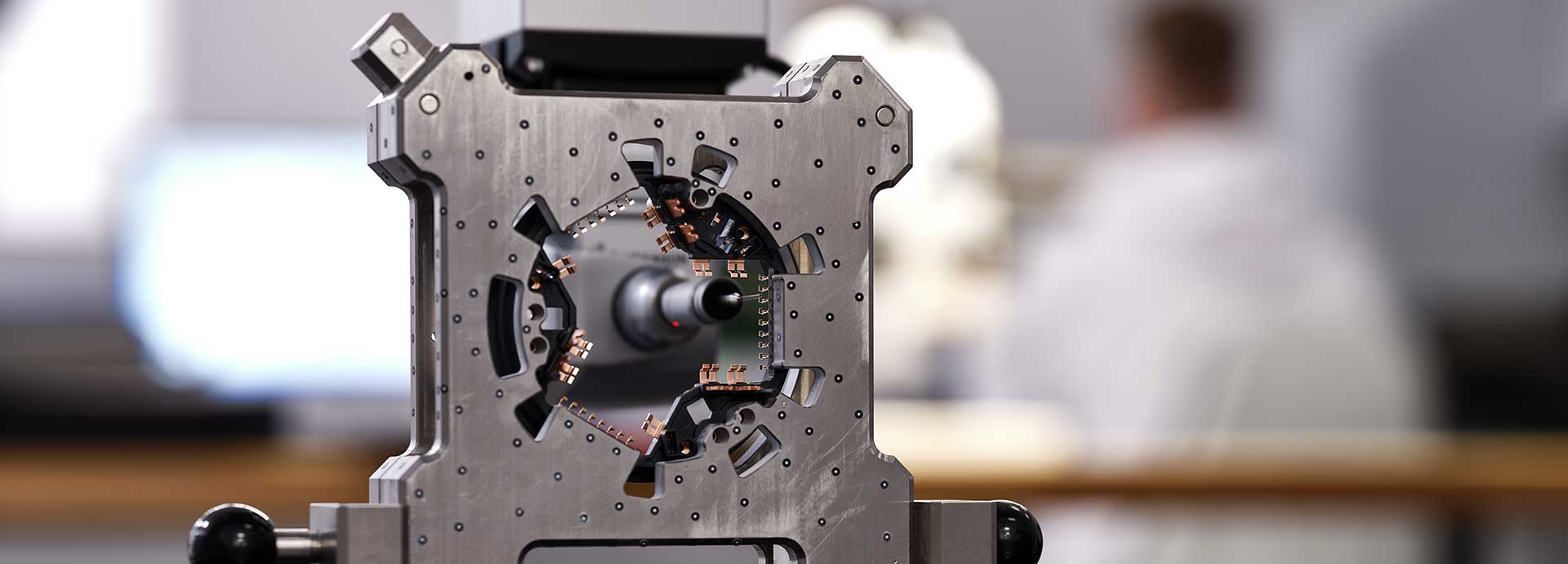

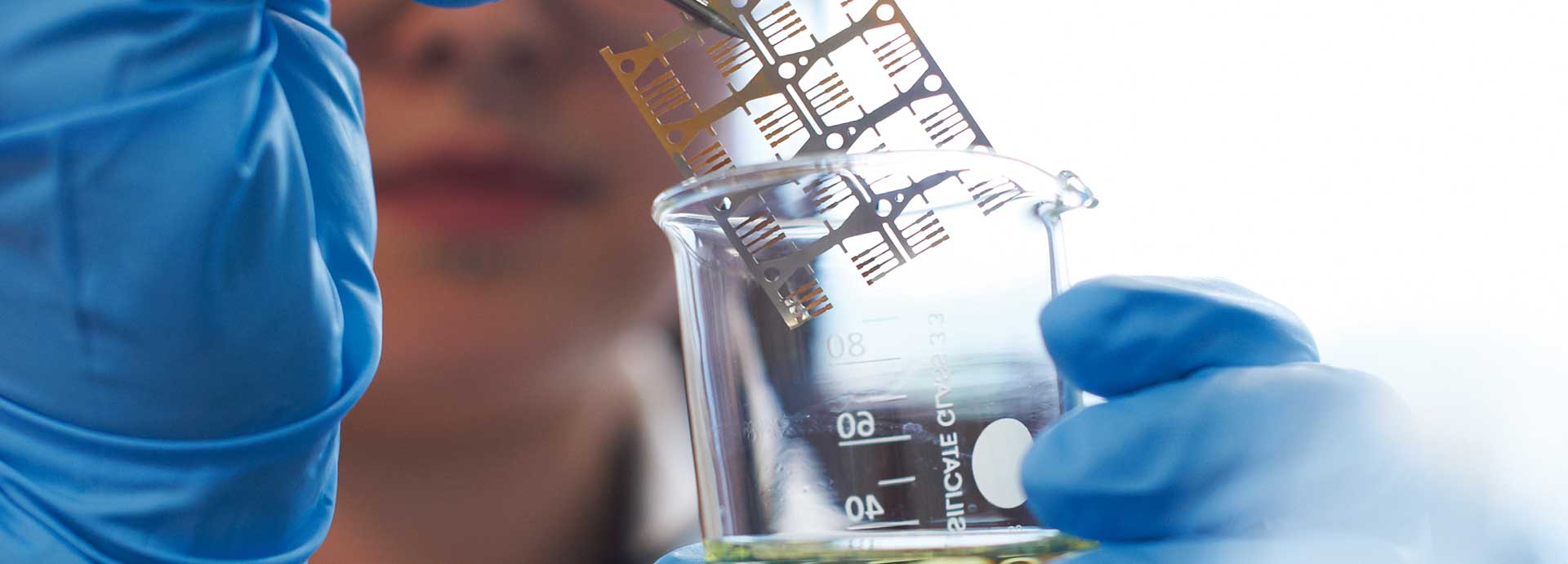

Bonding laboratory for

The mapping of customer-side wire-bonding techniques in construction and connection, as inline inspection of electroplated surfaces (ball/wedge – processes for chip bonding as well as wedge/wedge – processes for bonding hybrid components)

Electroplating laboratory for

- Electroplating bath analysis on a weekly basis

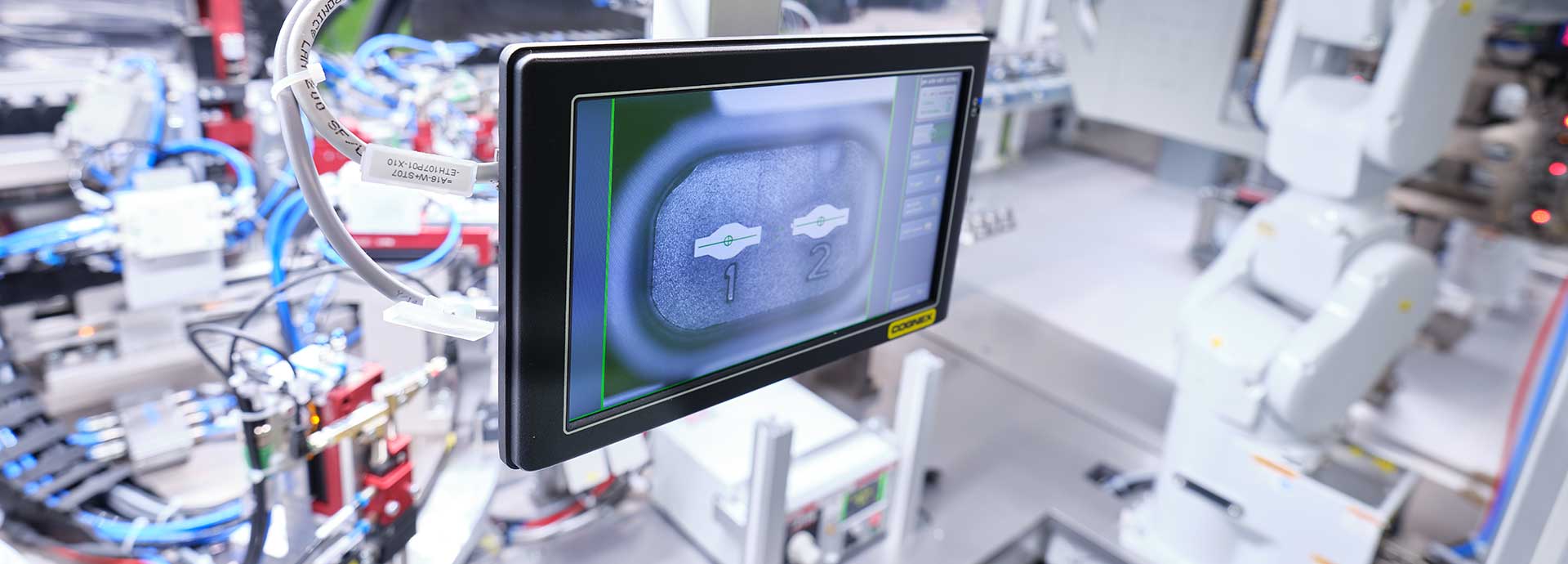

100% in-line inspection systems

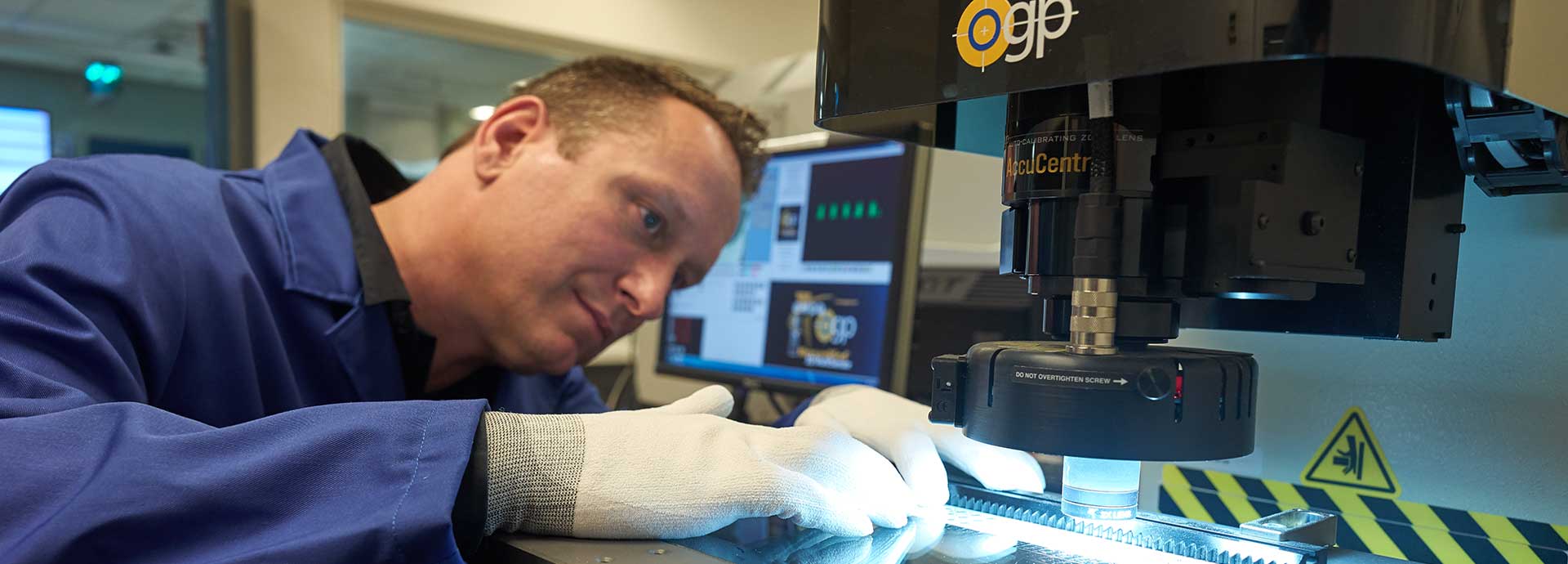

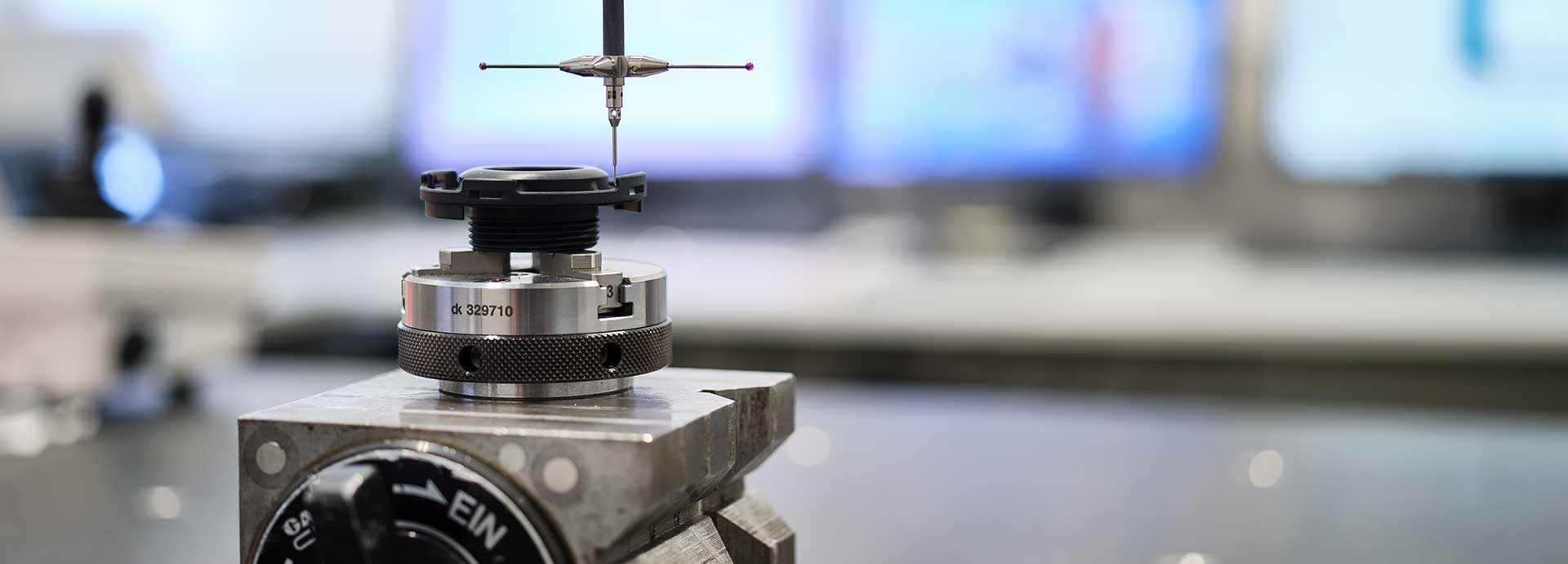

Measurement Technology

Possehl Electronics uses advanced inspection and measurement processes with which we systematically monitor our products from the prototype phase right through to series production. Our process engineers from the measurement department are involved as early as the development and design phase of the products. Also at the SOP, the prepared samples undergo tactile and optical measurement and are digitized using our custom-made in-house measuring tools.

Measuring room

- Tactile and optical 2D and 3D measuring machines

- Multisensor measuring machines (optical, tactile, white light)

- Optical digitizing system (ATOS III, GOM)

- Trace humidity measurement

- Laser transmission level testing Color and gloss measurement

- Surface tension testing

Incoming Goods Inspection

- Metal bands (tensile strength, elongation, hardness, roughness)

- Plastic (viscosity)

- 2D and 3D measurement

- Skip lot examination