Expertise and decades of experience: Etching technology at Possehl Electronics

Produced etched parts p.a.

~40000000 pcs.Materials

- Copper alloys with a thickness of 0.102 mm (4 mil) to 0.508 mm (20 mil)

- The most important copper alloys are C19400, C70250, EFTEC-64T and C15150 with different hardness and tempering to meet the various packing requirements.

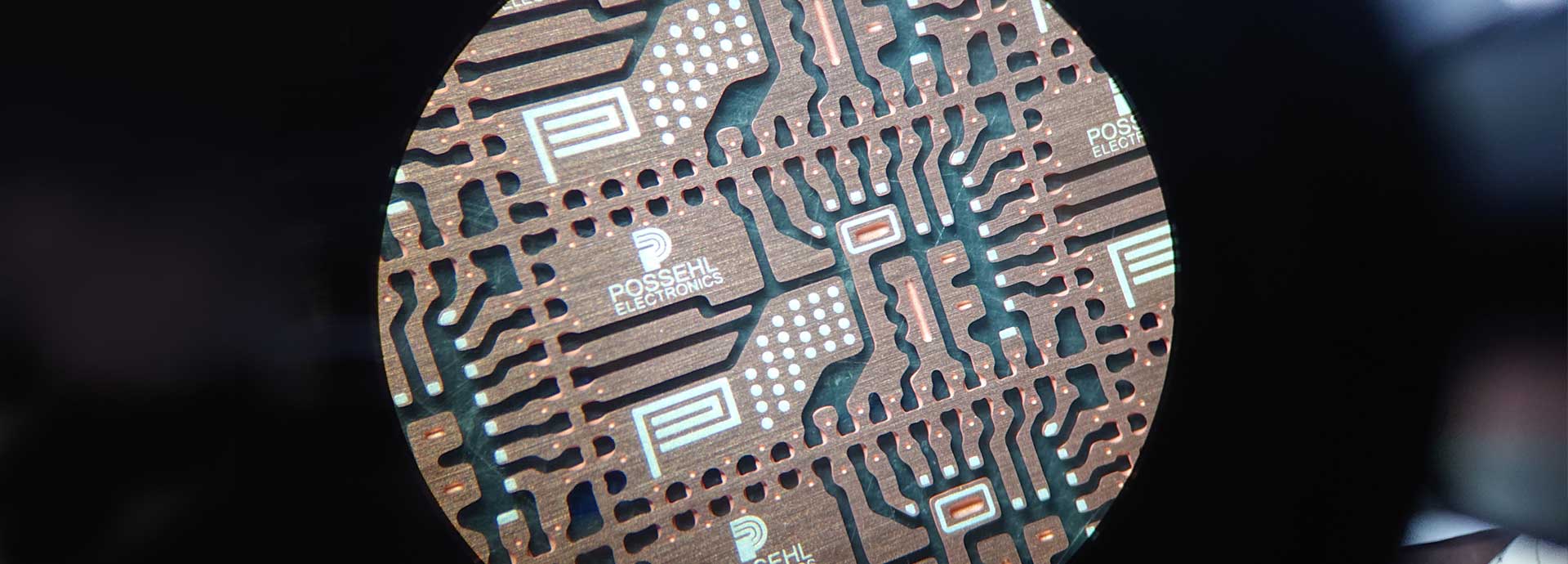

Surface coating

- By using the photo-mask technology we are able to achieve a positioning accuracy of +/-0.025 mm as well as a point-to-point spacing of at least 0.10 mm, both for Ag and for NiPdAu, on one or both sides.

- To improve the adhesion, we can roughen the copper surface on one or both sides prior to the coating process.

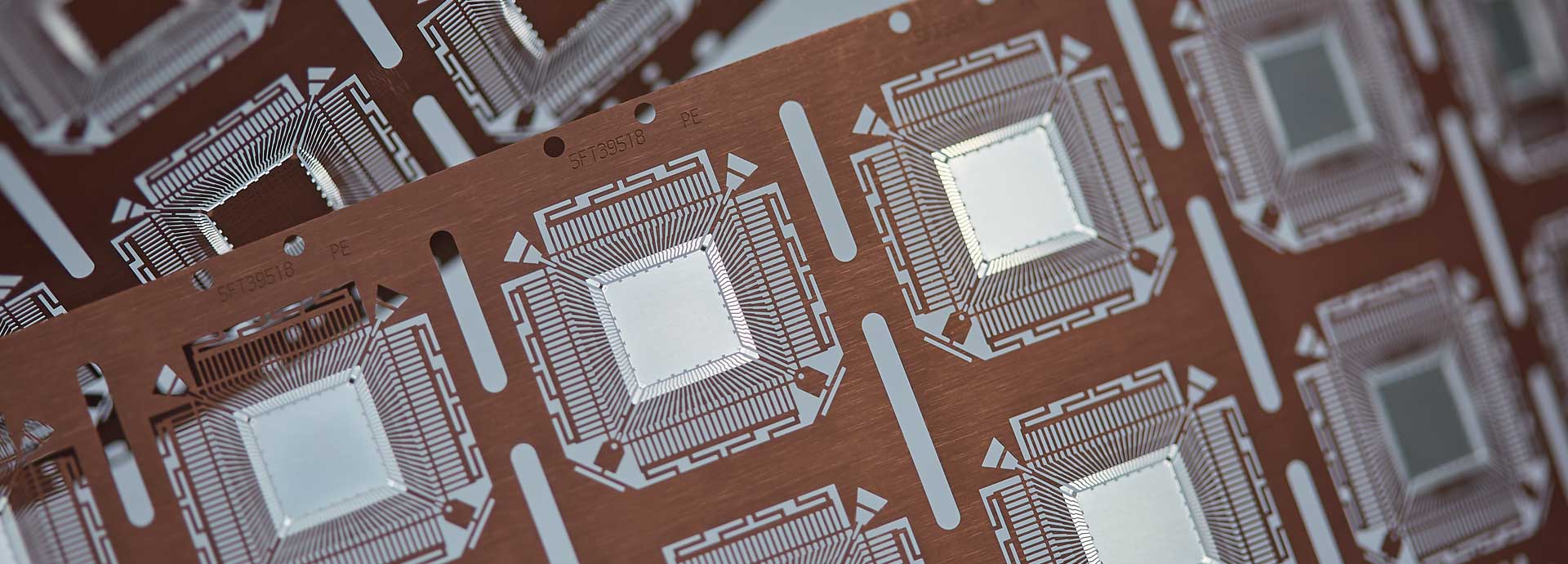

Etching

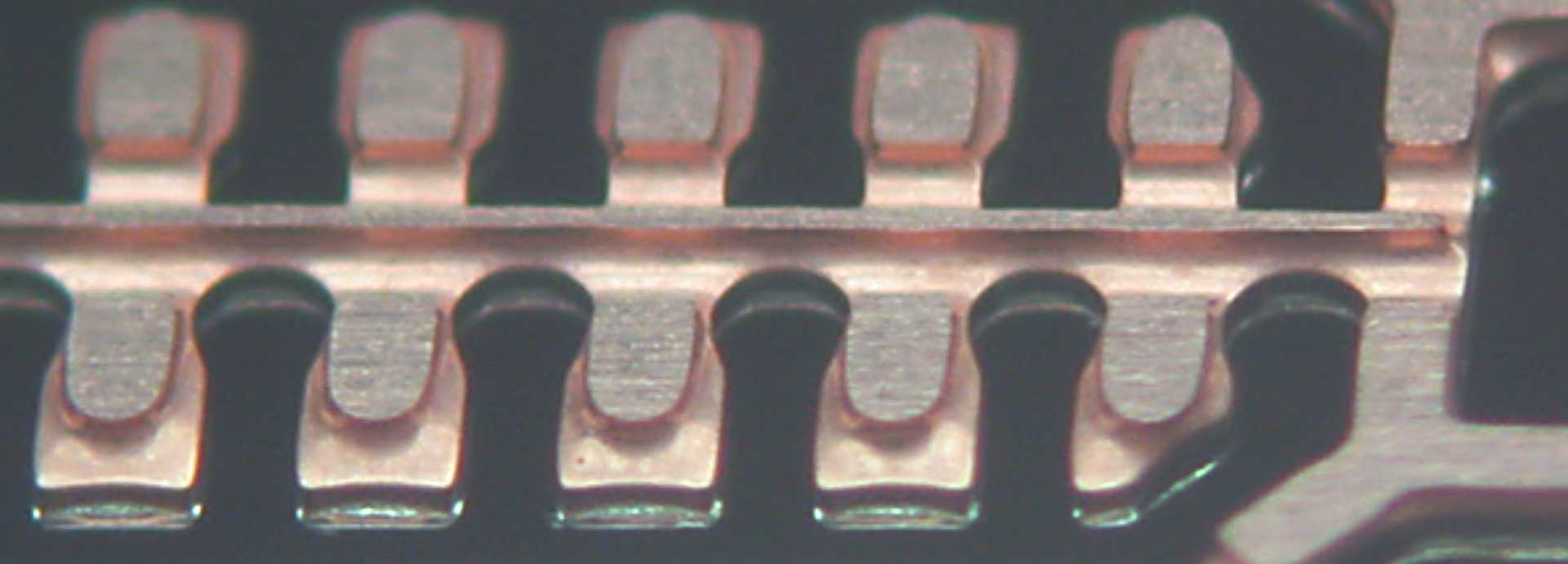

- We have the know-how to process highly complex designs with features such as cavity depth, deep etching, wettable flanks (dimples) and much more besides.

Treatment

- To improve the enclosure reliability (MSL-Level), we apply a proprietary treatment method to one or both sides of the copper surface to increase the mechanical locking performance.

Tools

- In-house production of printing templates and glass masks.

Machinery/Equipment

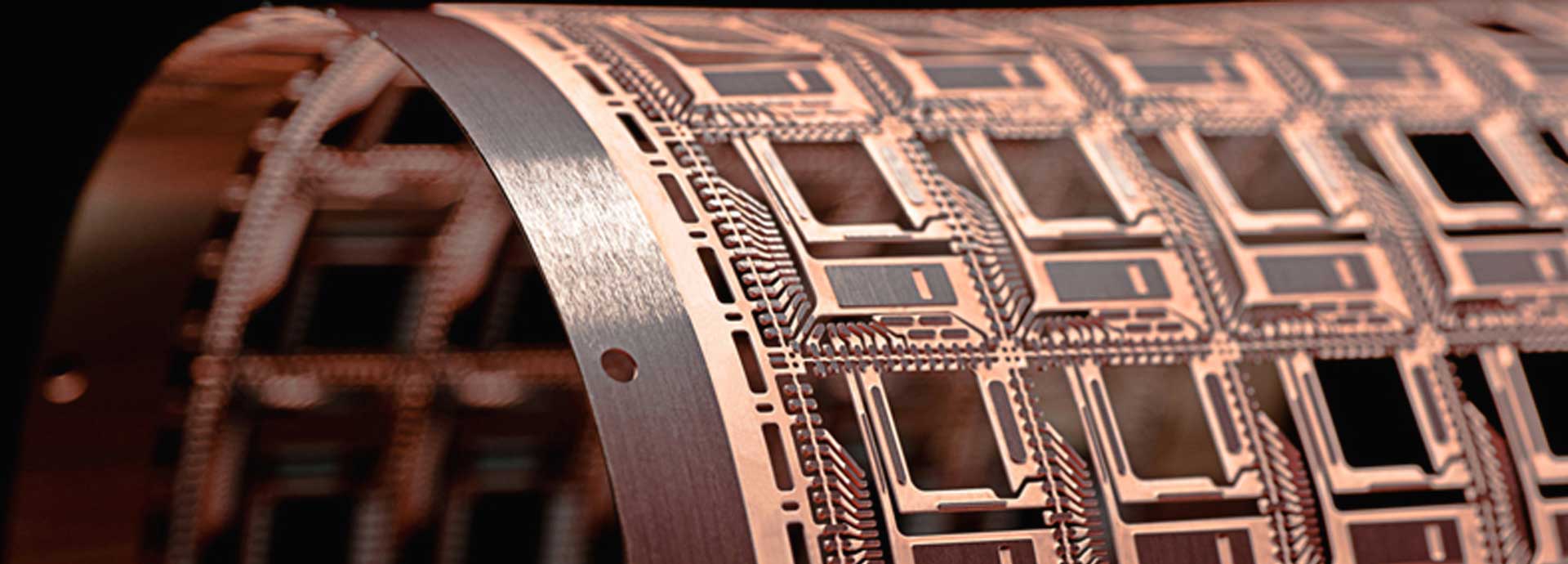

- High-speed reel-to-reel chemical etching process

- High-precision exposure process for design imaging

- Precise backside-strip-taping, lead/DAP offset, strip cutting

- Auto vision inspection systems are used in our process

Lead frame enclosure offer

- Enhance Cavity QFN-Design for a thinner enclosure

- Flipchip-QFN design with thin/long lines

- Deep half etching (on dambar) for 20mil QFN

- Selective coating both for an Ag and NiPdAu finish

- Etching ID marking on the pad

- Extension of the strip size up to 100×290 mm

- One-panel-wide lead frame design

- Super High Density design (>14,000 units per strip)

- Routable QFN lead frame design with 0.102 mm (4 mil) and 0.127 mm (5 mil) copper alloy thickness

- Fine Inner Lead Pitch up to 0.081 mm at a copper alloy thickness of 0.102 mm (4 mil)

- Multi-Pad Long Lead design QFN (under development)