Distinguishing features of Possehl Electronics: high- quality, ultra-clean surfaces with special properties

Plated flat-stock material p.a.

~14000kmMaterials

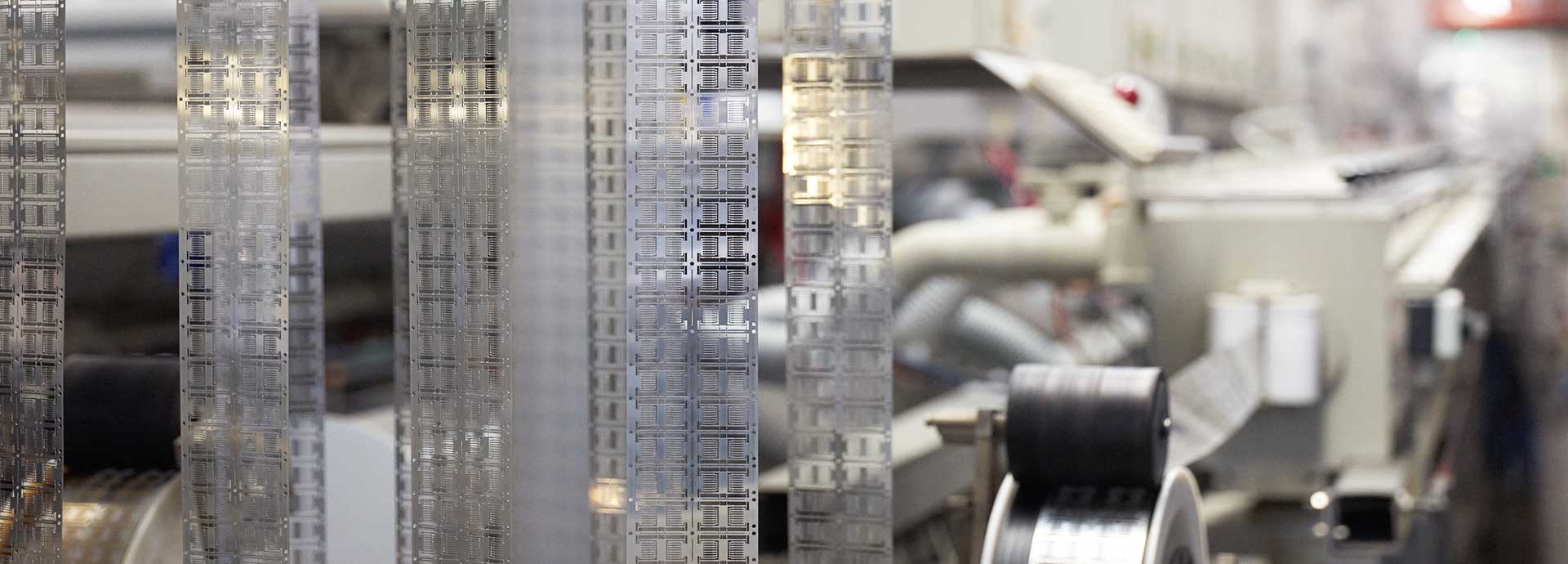

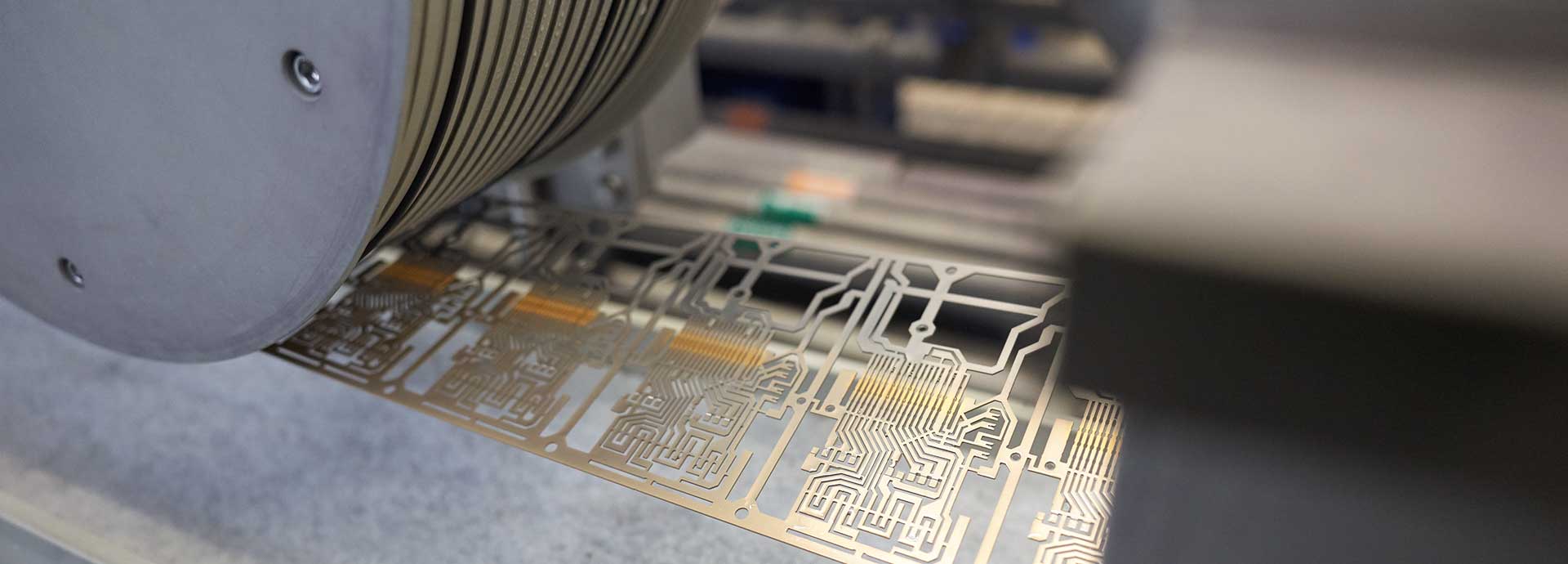

- Plating of processed flat-stock material (stamped lead frames, contacts)

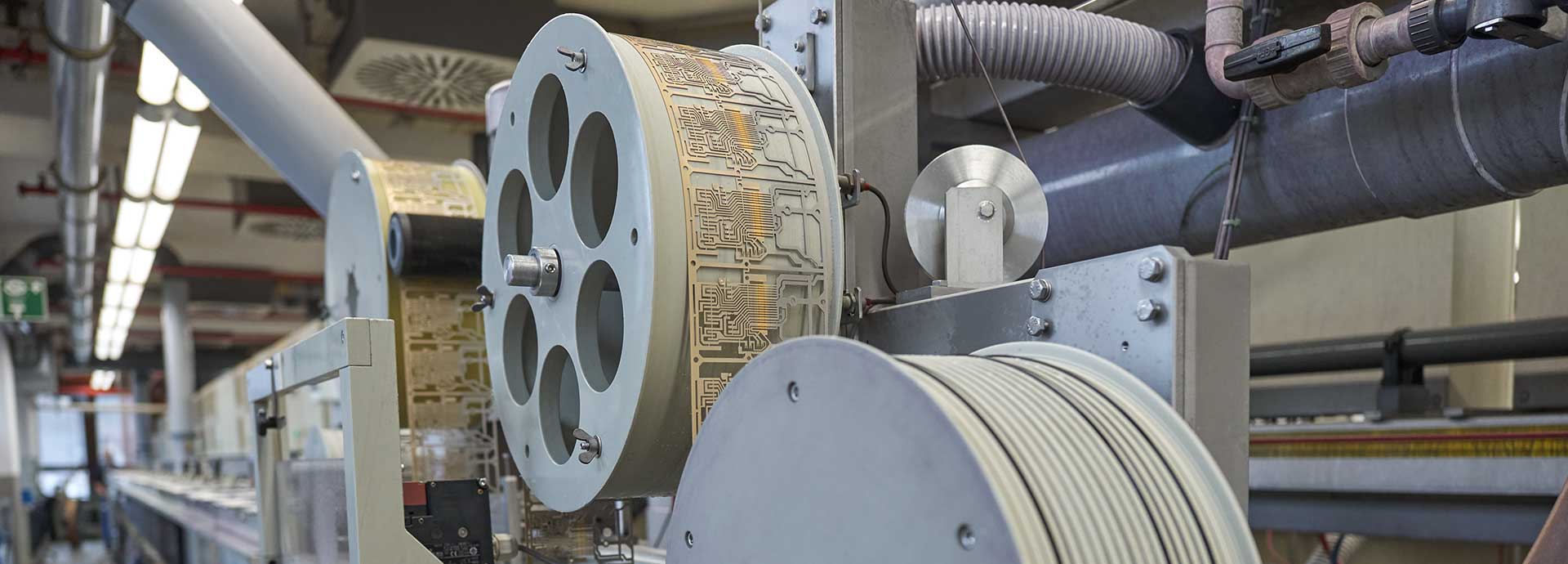

- Pre-plating of flat-stock material (semi-finished products) with a thickness of 0.03 to 1.50 mm and a width of 5 to 120 mm

- Coating of prototypes and loose falling parts

- Pre-plated flat-stock material

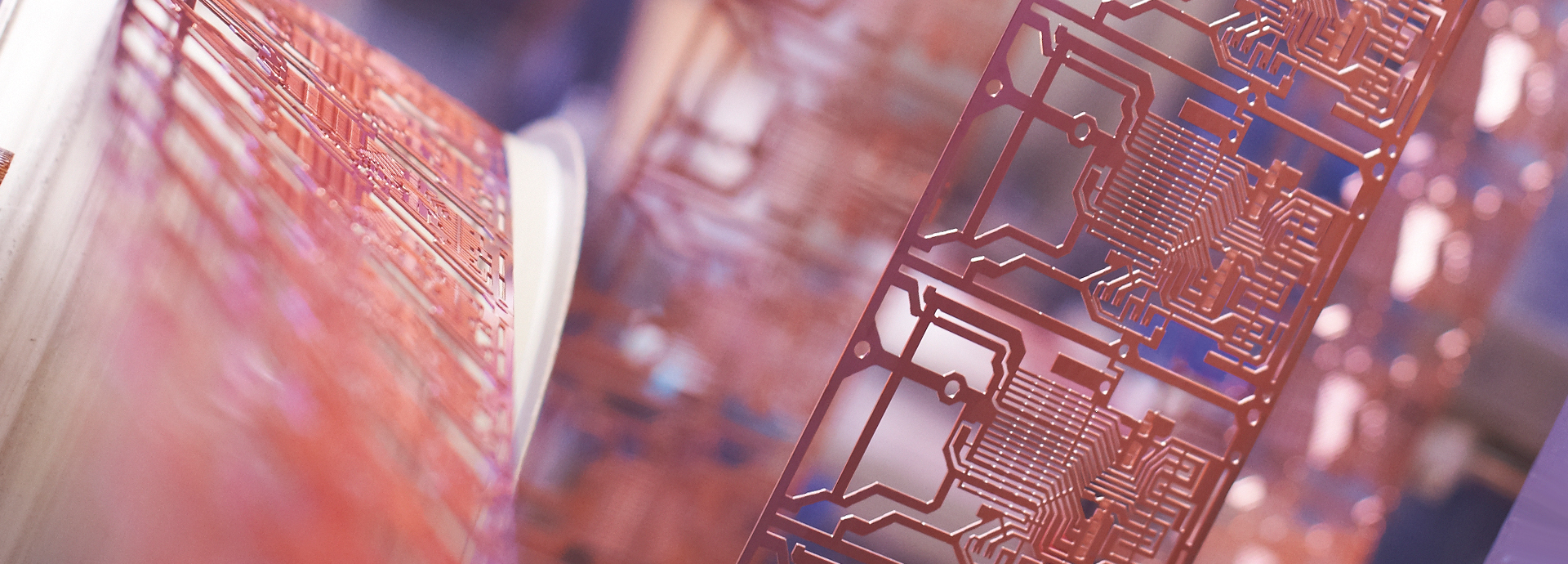

- Complex 3-D geometries

- Cu alloys, stainless steels and other unusual base materials

Surface

- All-over and selective plated coating of semi-finished products and lead frames by spot, strip, immersion and belt methods

- Producible surfaces: Cu, Ni, NiP, NiW, Sn, Ag, AuCo, AuNi, Au-pure, Pd, PdNi, ROHS Sn, In

- Pre-plated standard flat stock material

- Special alloys: SnAg, Indium,

- Process-specific surfaces for the press-in zone technology: AgSn alloys, Ni-sandwich, Ag/Sn/SnAg)

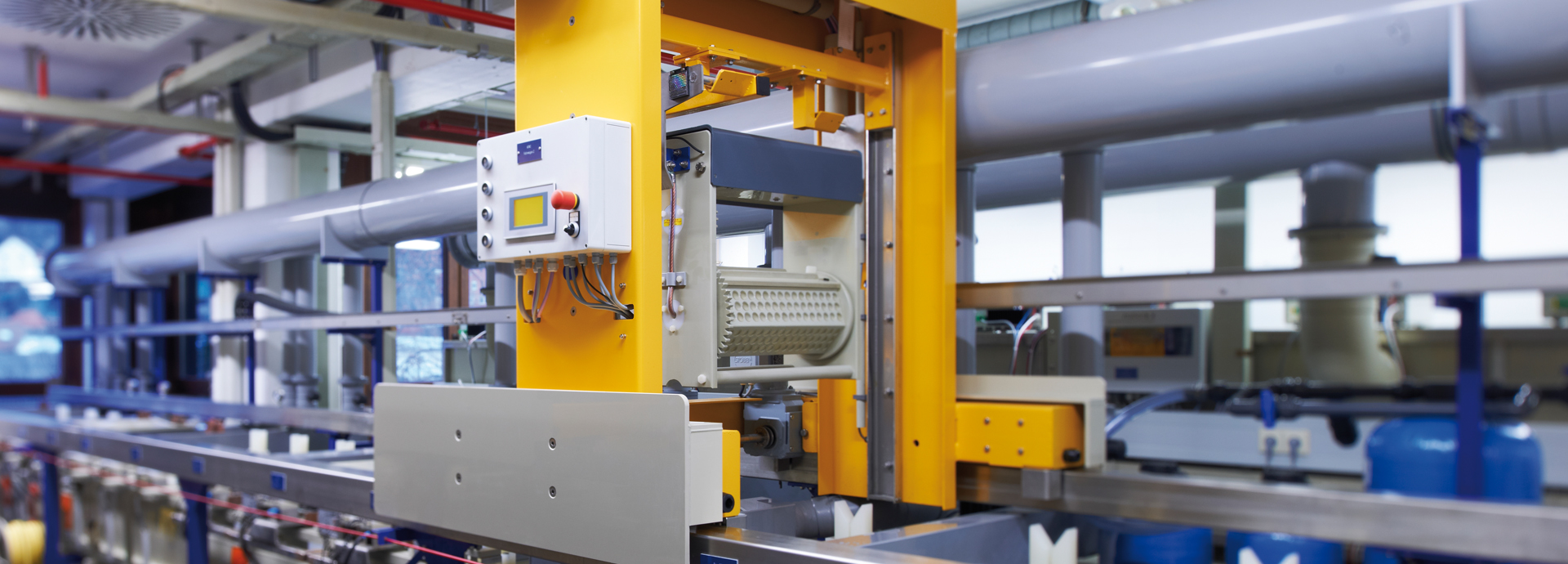

- Pre-treatment: Electro-polishing, ultrasonic, electric cleaning, degreasing, pickling, mechanical brushing and tape lamination

- Post-treatment: Micro-etching, passivation, lubrication and thermal conditioning (reflow)

- Both-side selective Ag photo-mask, NiPdAu photo-mask (high-precision coating tolerance),

- Full-Ni with mechanical mask spot Ag or full-Ni with mechanical mask belt Ag (newly installed plating system)

- Both-side mechanical mask spot Ag and both-side mechanical mask belt Ag

Tools

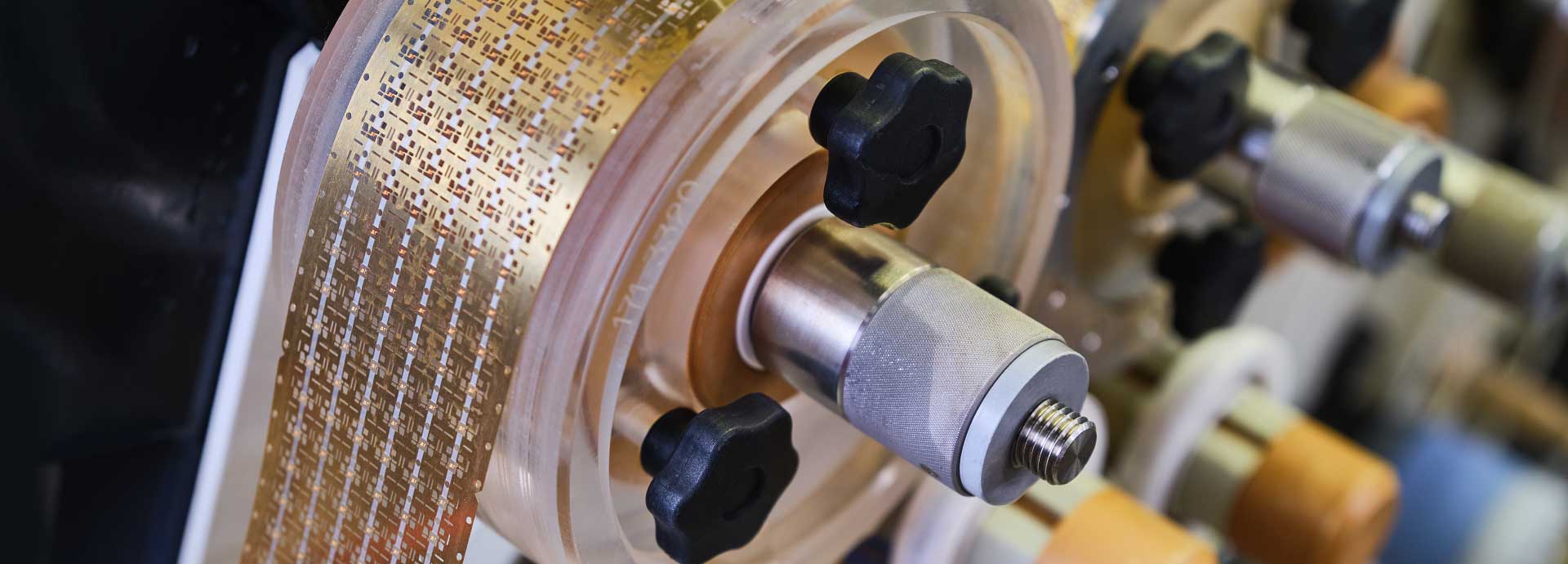

- Mechanical selective modules for spot and belt methods

- Photo-mask selective modules

- Brush modules for edge-reduced, one-sided plating of hard gold

- Selective immersion cells, belt cells, spot wheels and belt covers

- Jet cells for “high-speed” clipping

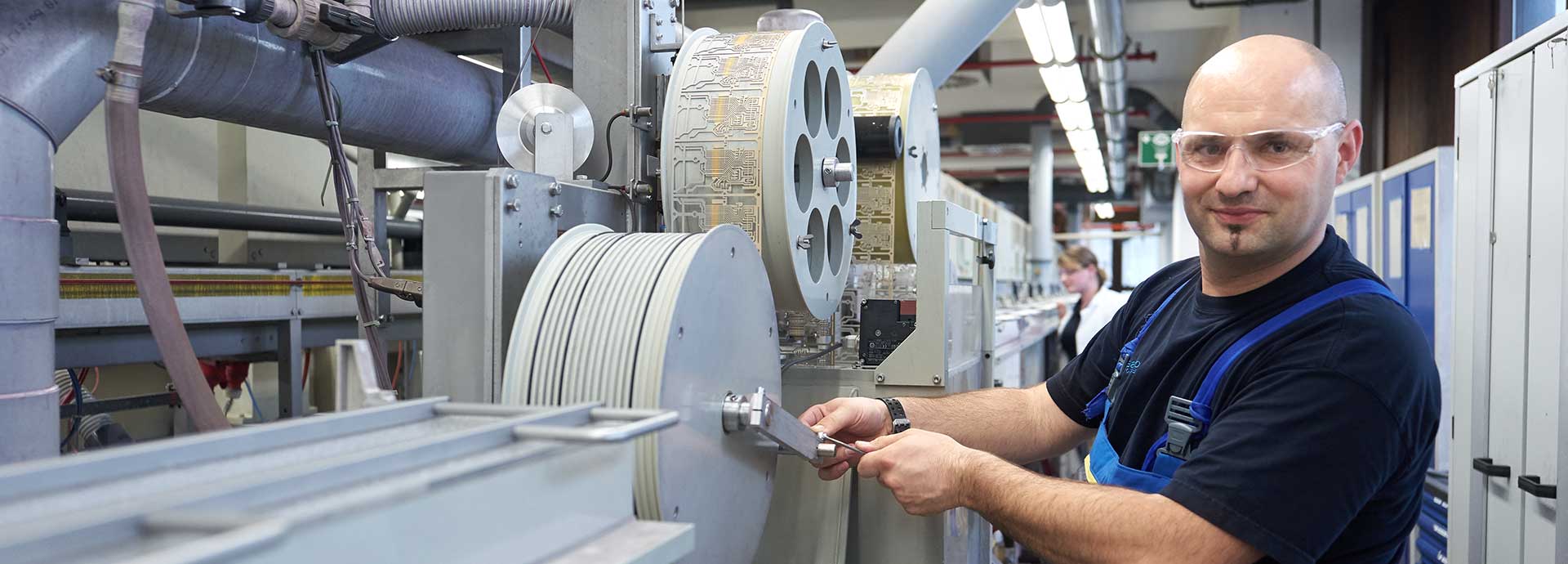

- In-house design and manufacture of electroplating modules

Machinery/Equipment

- More than 40 reel-to-reel electroplating plants

- Ultramodern prototype system for selective plating

- Fully automatic rack, drum, Vibrobot systems for single and loose falling parts

Technology highlights

- Production of highly pure, bondable surfaces

- Processes with minimized use of precious metals

- Processes for improving the mold adhesion

- Long-standing proven processes for producing functional surfaces for the production of specific electrical properties such as corrosion, soldering and welding ability, adhesive-plastic spray characteristics, bending-cutting performance.

- Plating of press-in zones