No hybrid component from Possehl Electronics without assembly and wiring technology

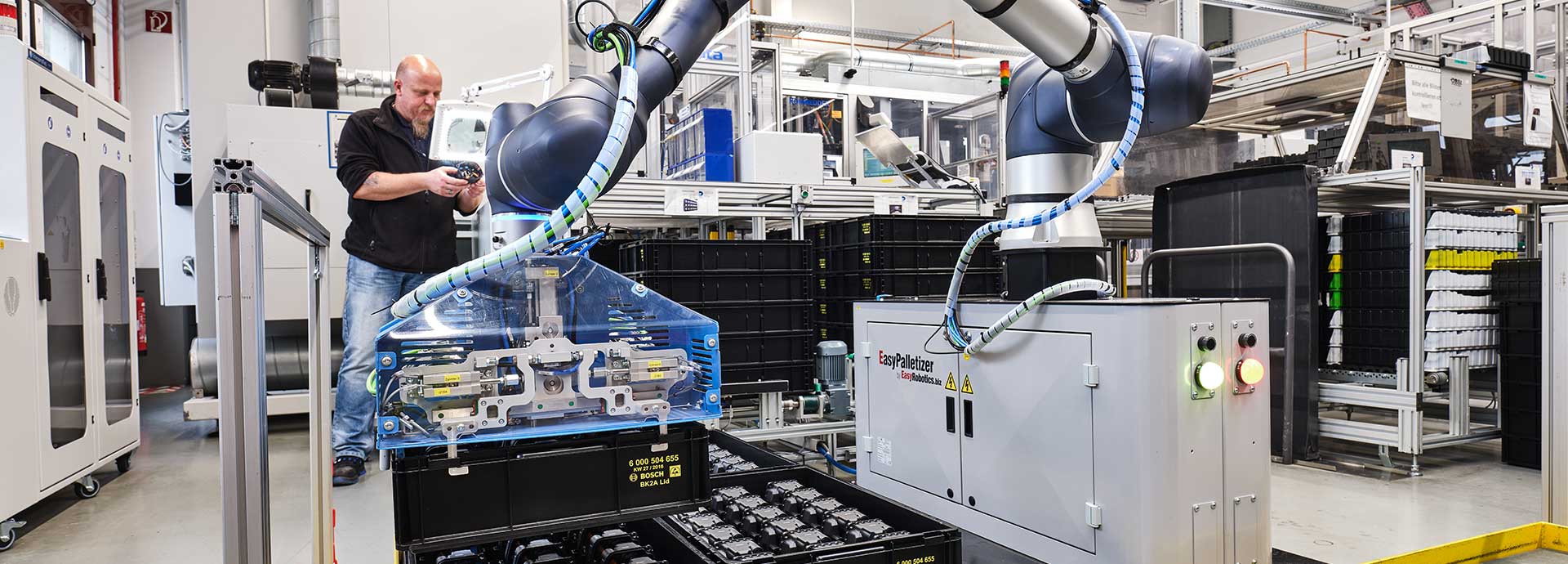

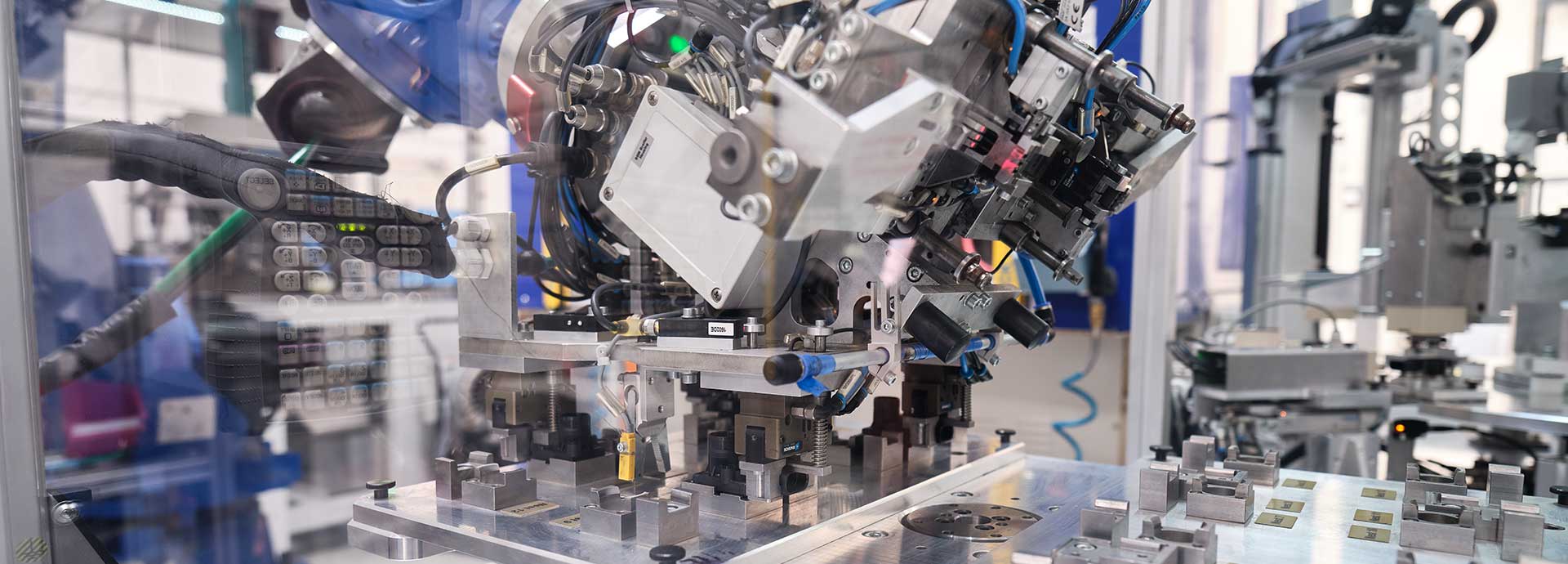

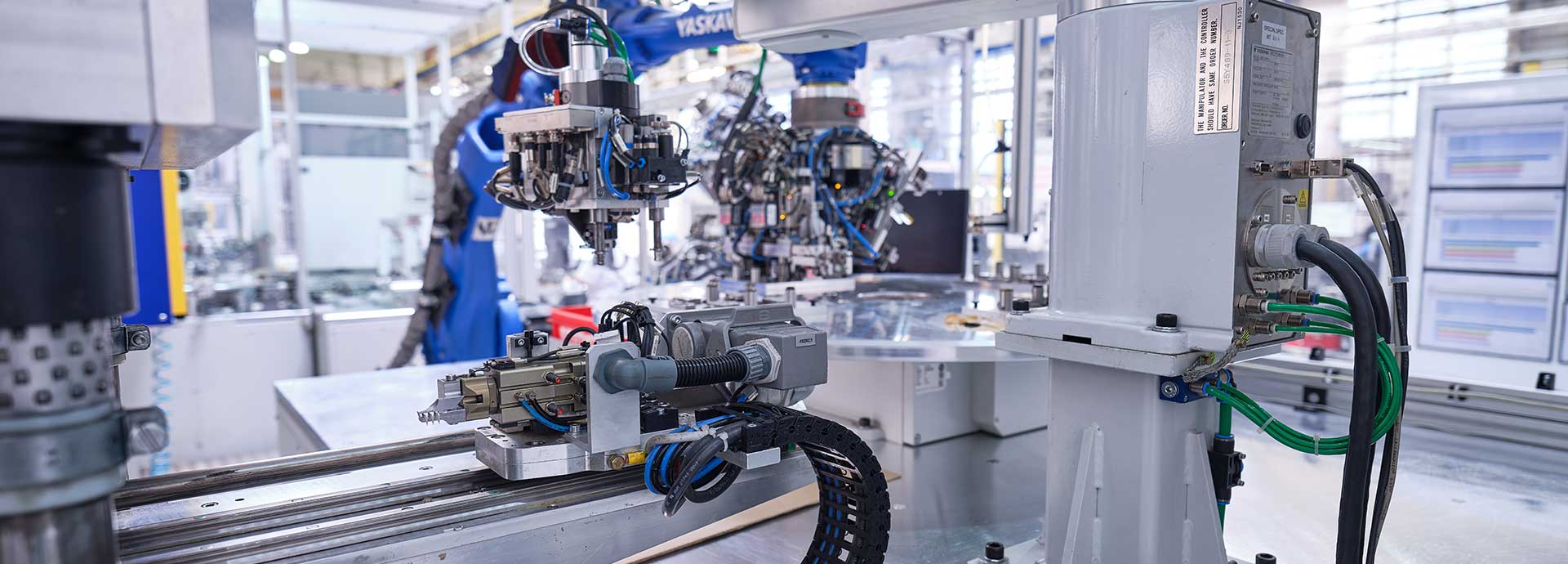

Robots in production

~210 pcs.Processed assembly parts p.a.

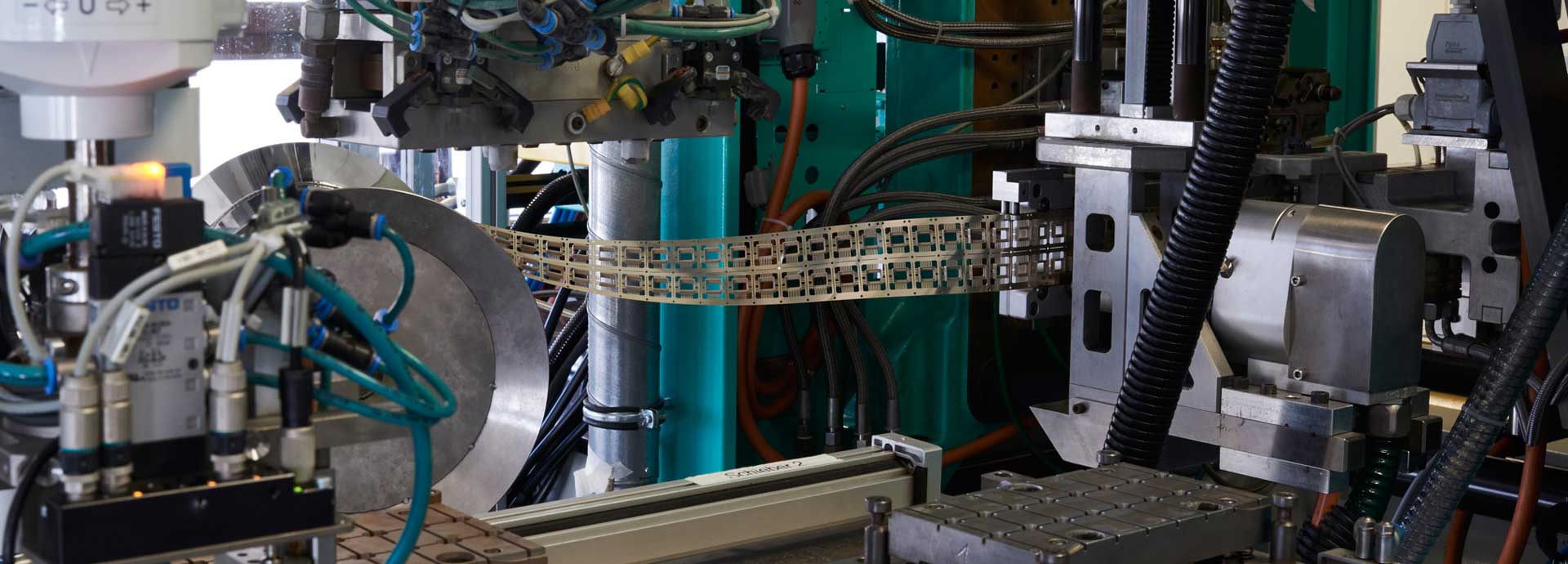

~610000000 pcs.Materials

- Precious metals

- Plastics

- Al-Cu roll clad bands

- Cu alloys

- Active and passive electronic components

Tools

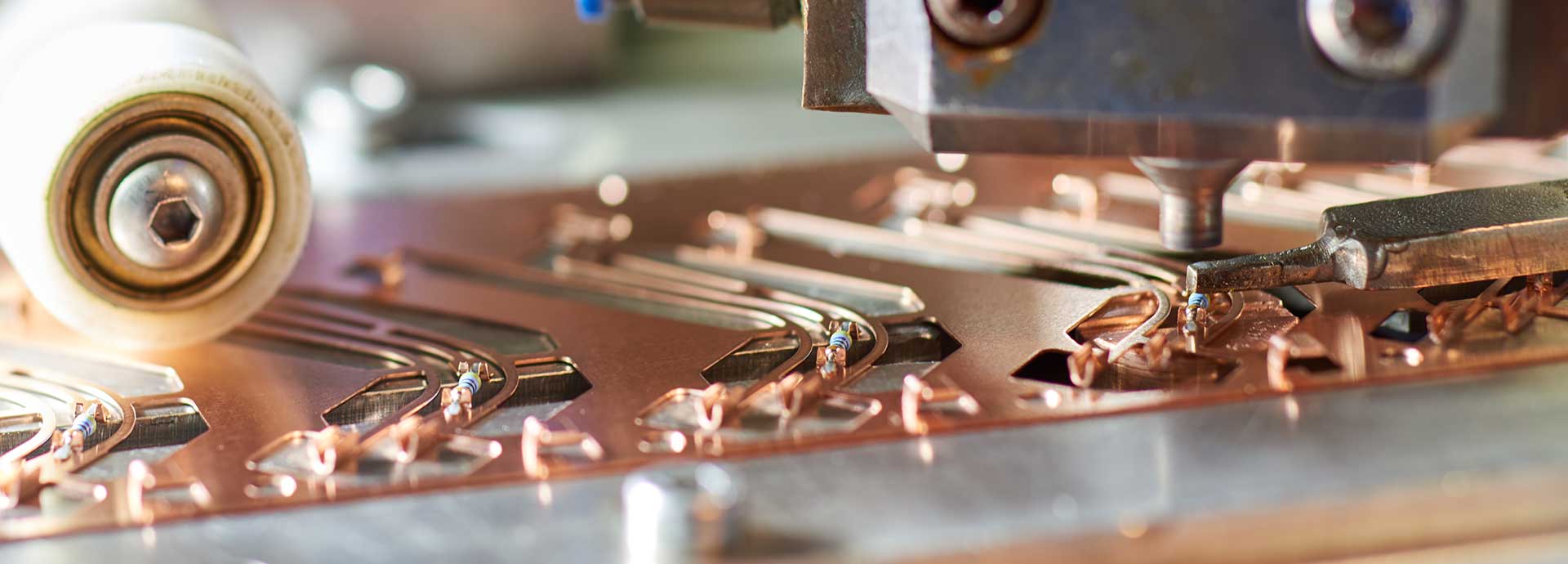

- High-precision stamping tools for bending and cutting processes

- Fixing tools

Machinery/Equipment

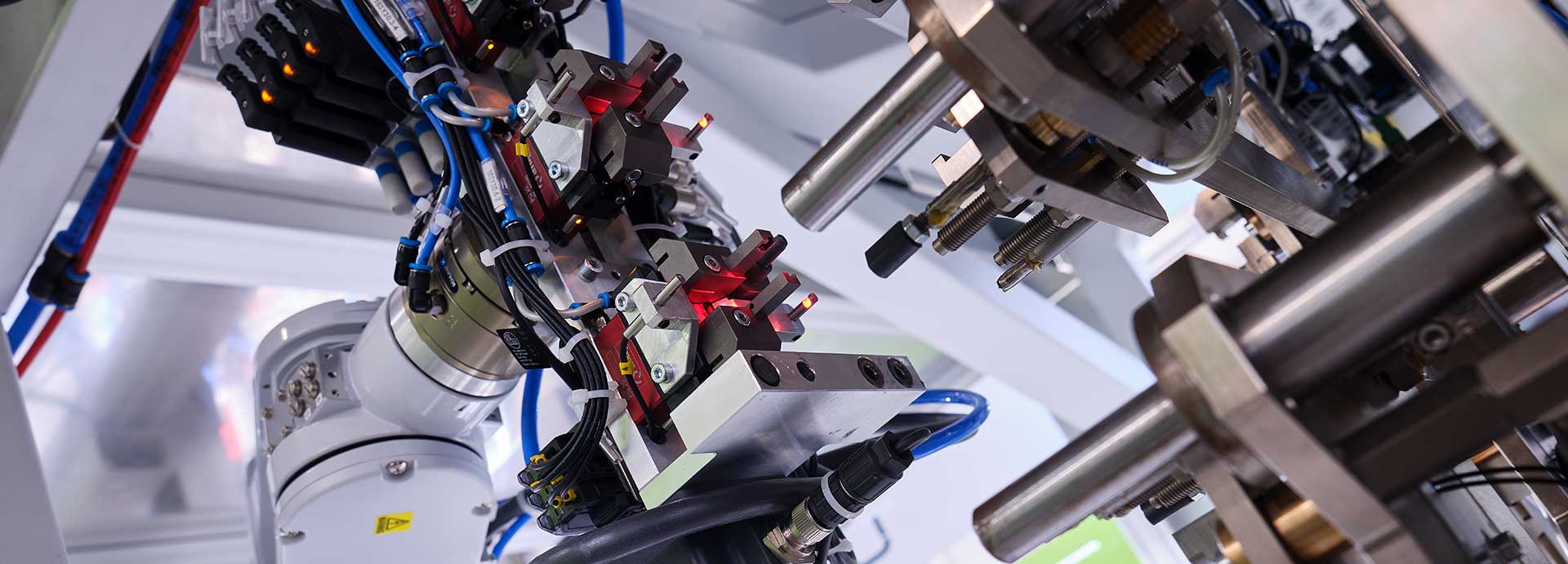

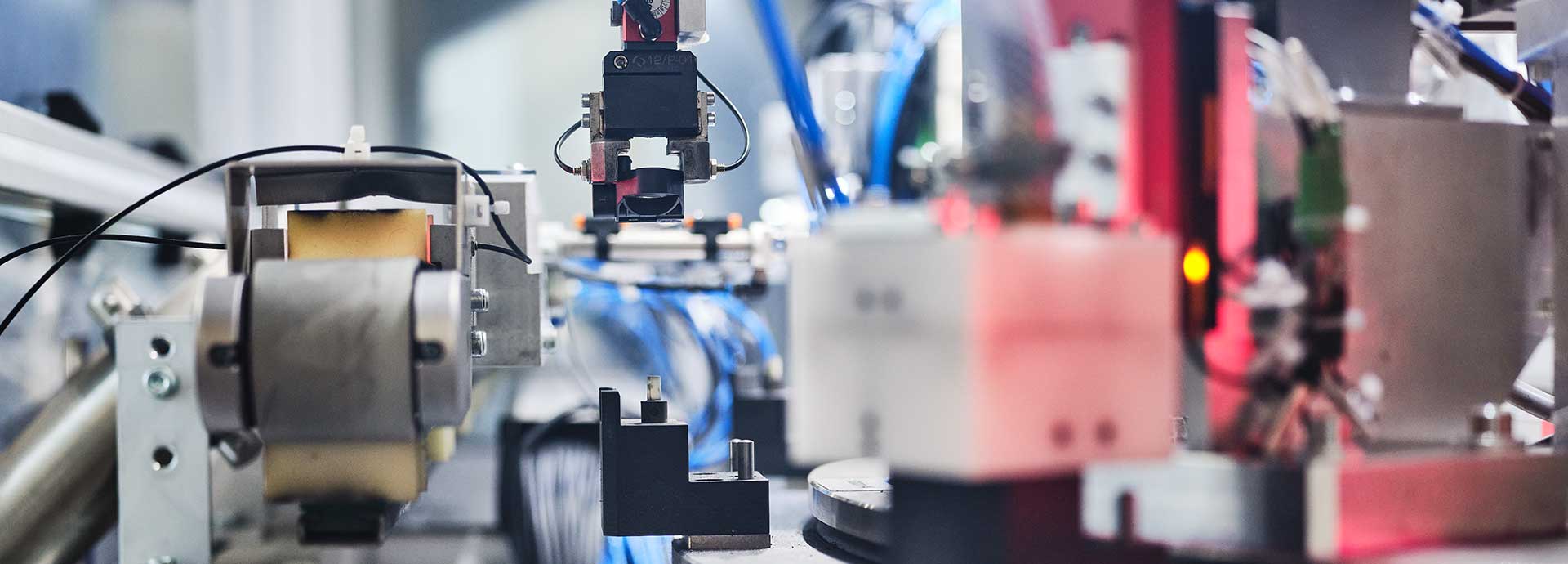

- Ultramodern fully and semi-automated assembly systems

- Laminating systems

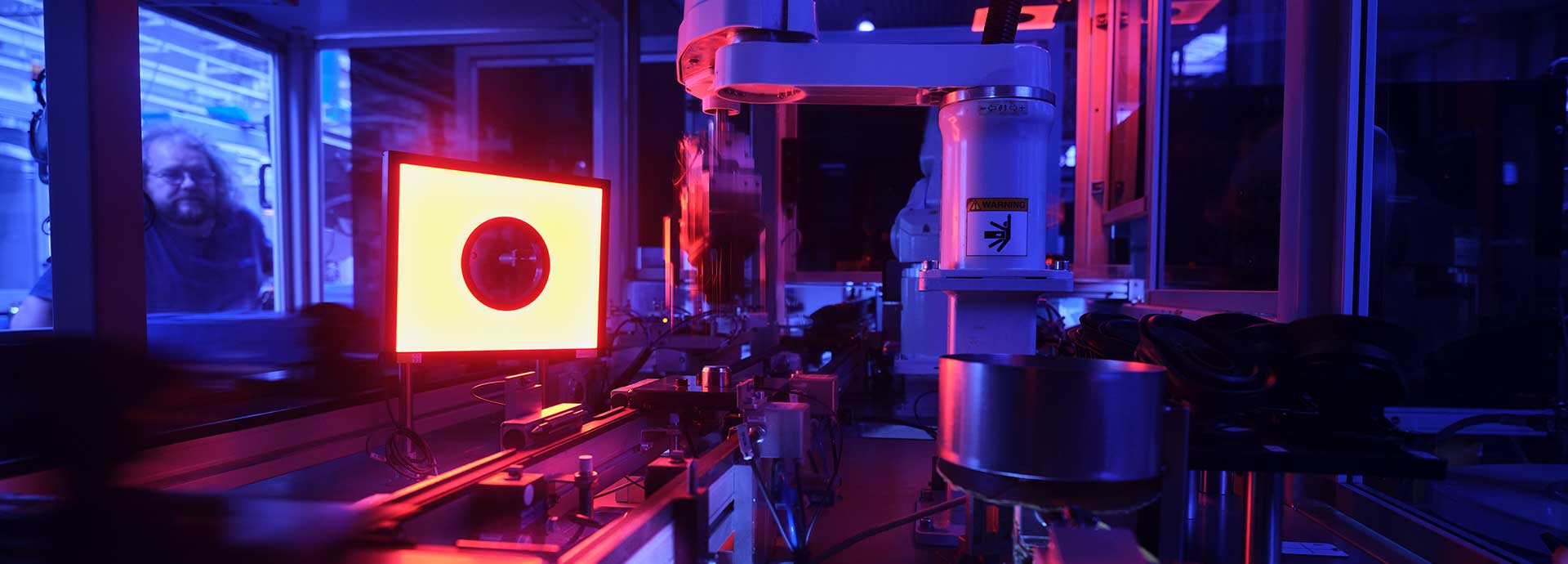

- Testing equipment

- Laser devices

- Optical camera systems

- Integrated automated manufacturing cells for 100% in-line inspection

Technology highlights

- Production under ESD conditions

- Production under clean-room conditions

- Processing of bondable surfaces

In connection technologies for the production of a hybrid component, the respective technology is adjusted to the product design and customer requirements in the development phase at Possehl Electronics. Laser welding and resistance welding are increasingly used, for example, in the integration of passive and active electrical components. When manufacturing components, technologies such as gluing, screwing, hot and cold caulking, clinching, stitching and pressing are applied. These connection processes are typically integrated into an automated production cell and the quality is monitored 100% in-line.