Did you know that a surface coater is not only responsible for surface processing?

When you apply your craftsmanship as a surface coater, our components and materials not only look more attractive, they usually also conduct electricity better or get a more resilient surface.

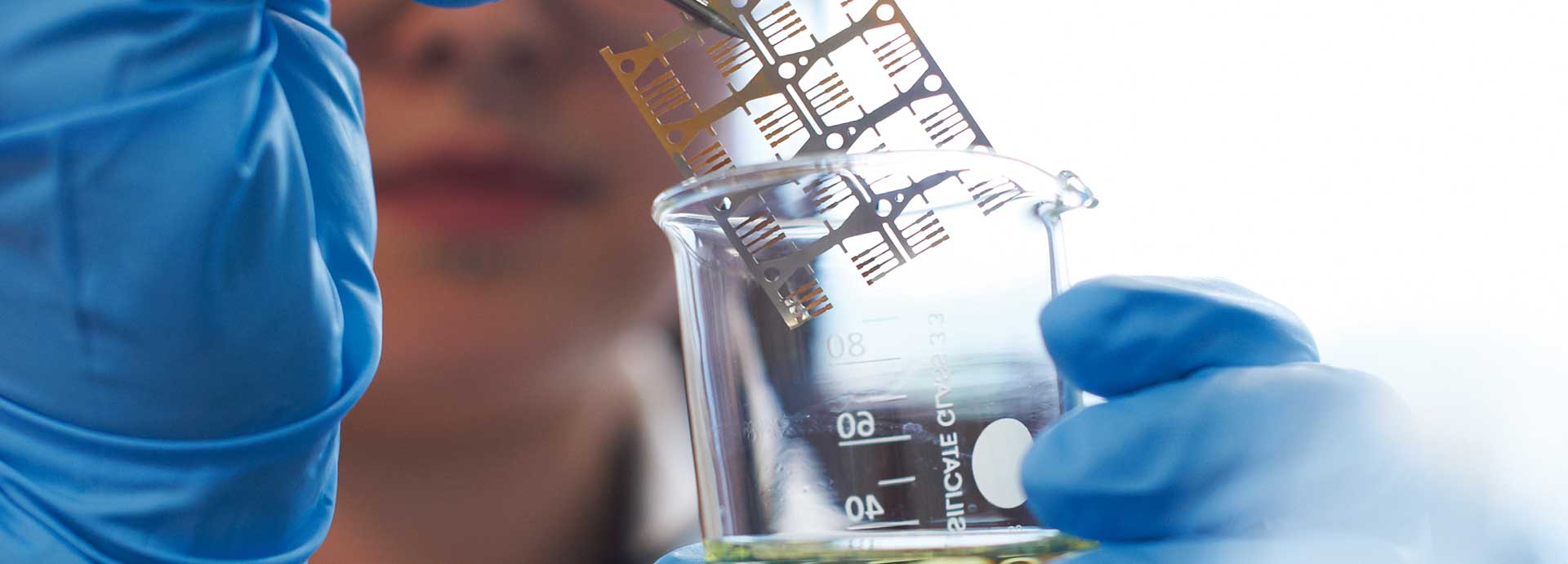

If chemistry was always one of your favorite subjects, you enjoy laboratory analysis work and want to work with state-of-the-art laboratory equipment, we have just the right apprenticeship for you in our surface technology department .

But you don’t just learn how to refine our products, you also become an expert in environmental protection along the way. As a surface coater you are also responsible for ensuring that no harmful contaminants are released into the environment. This is achieved by modern filter installations for air and waste water.

A team of specialists is at your side throughout your entire training to support you in all issues to do with your vocational training.

Training as a surface coater m/w/d

Requirements

School-leaving certificate with good grades in math, physics and chemistry

Duration of training

3 years

Training contents

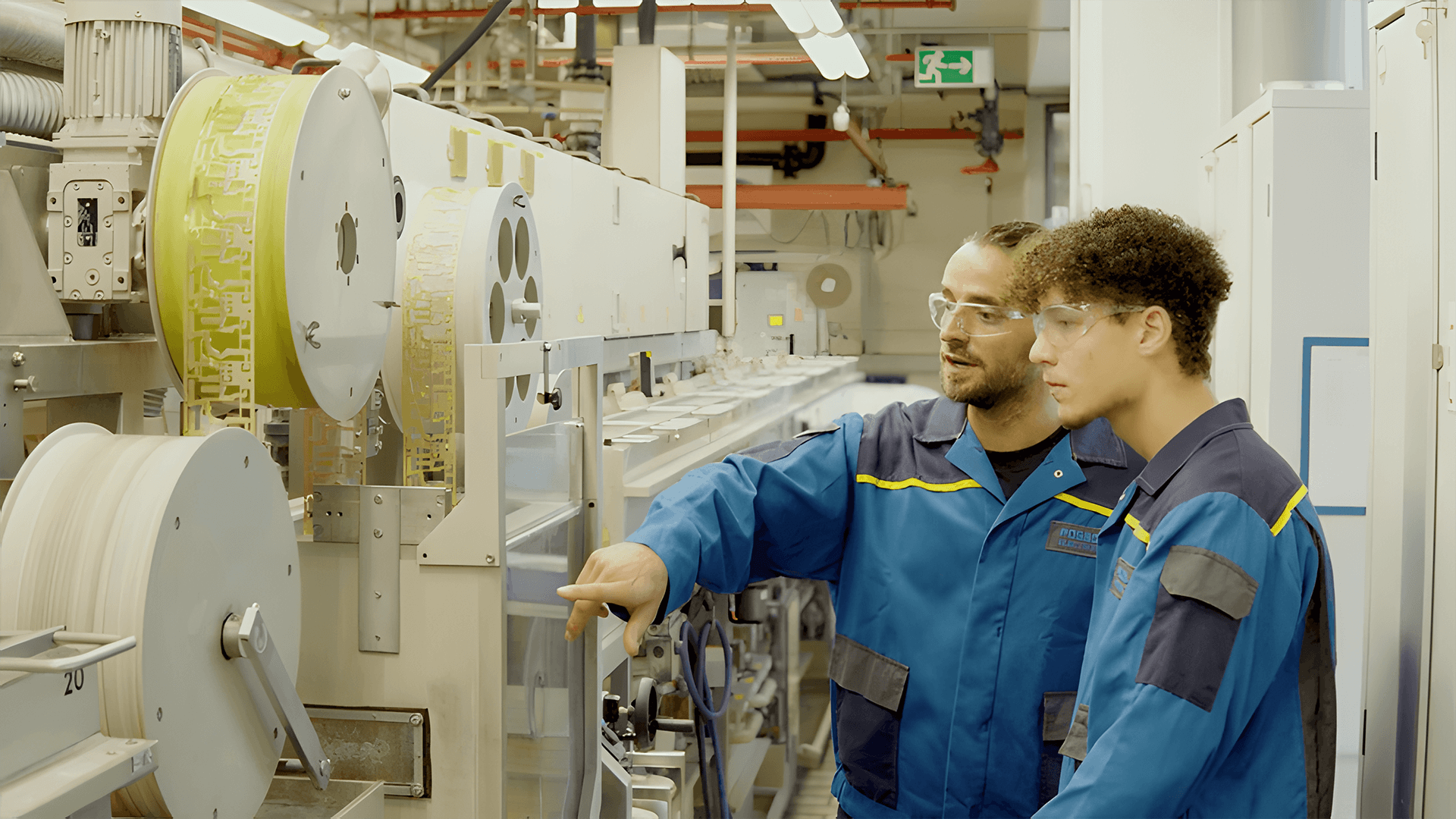

You begin with a comprehensive introduction to the electroplating work processes. The focus here is on all the important surface finishing processes such as copper plating, nickel plating, silver plating, gold plating and palladium plating.

… and besides

you learn how the separation of metal coatings from liquids (electroplating baths) works with the aid of computer-controlled systems, how the quality of these coatings can be tested and influenced, how the electroplating baths are analyzed and which enviroment-friendly processing techniques are applied.

Training plan:

- Introduction to the electroplating production department

- Surface finishing in parts electroplating

- Surface finishing in strip electroplating

- Analyses in the chemistry lab

- Latest environmental technology

- Quality control of metal coatings

After training,

you can be employed, for example, as a surface coater in the strip electroplating, parts electroplating, waste water system or the chemistry lab.

…and if you wish

further training opportunities are open, for example, as a master or technician.

Have we inspired you? Then take that decisive step towards a secure future at Possehl Electronics and become a team member in the Future League!

Apply immediately for the training start 2024.

Possehl Electronics

Deutschland GmbH

Enztalstraße 6

75223 Niefern

Your contact

Mr. Jochen Laun

Tel. +49 7233 69-214

Please make sure that your application does not exceed 5 MB in size. Permissible file formats are .pdf und .jpg. We also request you to submit your papers in a single document.